CEREFIBER®

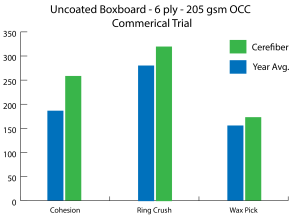

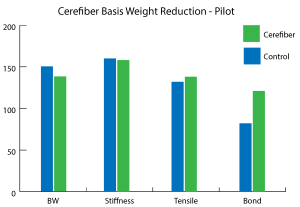

Ceregel-A ® encapsulation technology opens the door for game changing strength increases in paperboard. By combining starch and fiber with Ceregel-A ®, Cerealus and The University of Maine have developed a meaningful and unique solution to paperboard manufacturers allowing them to increase the strength of their products.

This leverage technology gives the paperboard maker the ability to trade that strength for a variety of economic benefits. Reduced dependency on purchased fiber, ash increases up to 10% of the furnish, enhanced productivity, and lower basis weights to name a few of the most obvious. This technology can be used with most conventional wet end retention and drainage programs and existing equipment with minor modifications. Cerealus has raised the bar on strength development technology, and consistently out-performs other dry strength programs.

Polymers, both natural and synthetic have been developed through the addition of which increase total bonded area and can enhance the operational efficiency of paper/paperboard machines. CMC,starch, polyacrylamides, polyamines and amides, are to name a few of the myriad of combinations available to the paper/paperboard maker today.

The most significant limiting factor in the use of these additives; however, is the matrix of cost, performance, and rate limiting aspects of their utilization. E.G. conventional wisdom limits the use of wet endstarch to about 1% due to the absorption capacity of pulp and the nature and chemistry of the wet end. Some technologies are limited in their technical effect due to the loss of other properties such as bulk or printability in printing and publishing grades. Other additives may have limits of use by regulatory agencies, such as the FDA in the US. Finally, the strength development may just be too expensive relative to other options.

The most significant limiting factor in the use of these additives; however, is the matrix of cost, performance, and rate limiting aspects of their utilization. E.G. conventional wisdom limits the use of wet endstarch to about 1% due to the absorption capacity of pulp and the nature and chemistry of the wet end. Some technologies are limited in their technical effect due to the loss of other properties such as bulk or printability in printing and publishing grades. Other additives may have limits of use by regulatory agencies, such as the FDA in the US. Finally, the strength development may just be too expensive relative to other options.